2025 Early Spring "Meng Ding Gan Lu" (Mengding Ganlu / Sweet Dew) A+++++ Grade Green Tea, Si Chuan Province.

Regular price$9.99

/

- Free shipping worldwide

- Tax and import charges included

- First order 10% Off, Code: TMK2025

Origin: Mengding Mountain, Ya’an, Sichuan Province, China

Tea Characteristics:

-

Dry Leaf Appearance:

Tightly curled like tiny spirals, adorned with fine silver tips resembling pine needles dusted with the first snow. The color showcases an "ivory base with emerald tips." -

Liquor Color:

Tender green with a light jade hue, shifting to a subtle apricot tone after the third infusion. Crystal clear and luminous throughout. -

Aroma Profile:

Initial whiffs reveal a fresh, delicate fragrance, followed by a rich orchid scent with sweet peach undertones. As the cup cools, a refreshing rock sugar coolness emerges. -

Flavor Layers:

A crisp, sweet entry gives way to a lingering chestnut aroma, with a throat-soothing finish that stimulates salivation. Even after seven infusions, a gentle loquat leaf sweetness persists. -

Spent Leaves:

Unfurled buds and leaves resemble orchid petals, displaying a tender yellowish-green base with a silky, vibrant texture.

Brewing Recommendations:

-

Vessel: Gaiwan or glass cup

-

Water Temperature: Pure or spring water (80-85°C). Avoid pouring boiling water directly onto the leaves.

-

Gaiwan Brewing:

Use 3g of tea with 150ml of water (1:50 ratio). Pour water gently along the cup’s edge in a steady stream. Steep briefly and pour immediately. After the fourth infusion, slightly extend the steeping time. -

Glass Cup Brewing:

Use 2g of tea with 300ml of water. Pour 1/3 of the water first, add the tea, swirl to appreciate the leaves, then fill to 70% capacity, topping off with a final pour.

Heritage & Terroir:

Mengding Ganlu hails from the golden tea belt at 30°N latitude, atop Mengding Mountain in Ya’an, Sichuan. With an average annual temperature of 15.4°C, year-round mist, weakly acidic sandy loam soil, and 2,000 hours of sunlight, this terroir nurtures an ancient tea legacy. Legend traces its origins to Wu Lizhen of the Western Han Dynasty, who planted seven tea trees. By the Tang Dynasty, Emperor Xuanzong designated it a tribute tea. The Song Dynasty immortalized it with the verse: "Water from the heart of the Yangtze, tea from the peak of Mengshan."

The 2025 early spring harvest is sourced from the core production area at approximately 1,000 meters elevation, hand-picked to the exacting standard of one bud and one leaf.

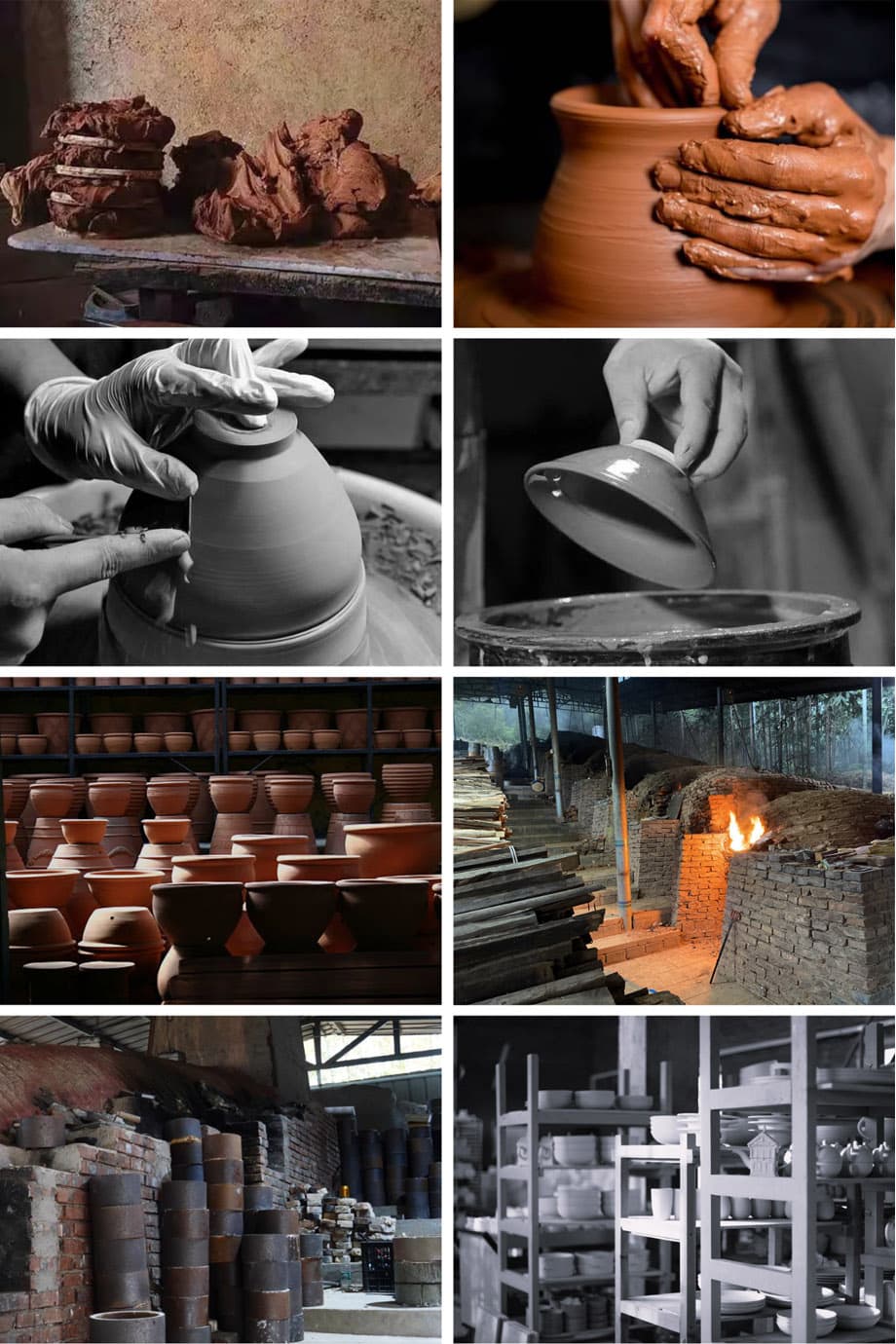

Craftsmanship:

Following the ancient methods of the Ming Dynasty’s Tea Notes, the leaves are air-dried for 12 hours, then meticulously processed through a "three-fry, three-knead" technique:

-

Initial Frying (160°C): Locks in freshness in an iron wok.

-

Shaping (Bamboo Whisk): Forms the leaves through tossing and kneading.

-

Second Frying (90°C): Enhances the aroma.

-

Cloth Kneading: Reveals the fine silver tips.

-

Final Frying (70°C): Sets the fragrance.

This process crafts the traditional "cicada wing curl" shape. A 24-hour low-temperature charcoal roasting seals in the tea’s signature "Three Charms of Sweet Dew": orchid charm, chestnut charm, and rock sugar charm.

Free shipping

Delivery Time:

Delivery time = Process time + Shipping time

1). Process Time:

Processing Time: 1-3 days

2). Shipping Time:

Standard Shipping: 8-15 business days.

Express Shipping: 5 -7 business days.

Some special countries will take more time. Learn more: Shipping Info.

Our Guarantee:

We accept returns within 30 days of receiving your package.

Learn more about our Return Policy.